How do you ensure EV Roadworthiness?

Walk-round checks and roadworthiness are as important with electric vehicles (EVs) as with any conventional driveline.

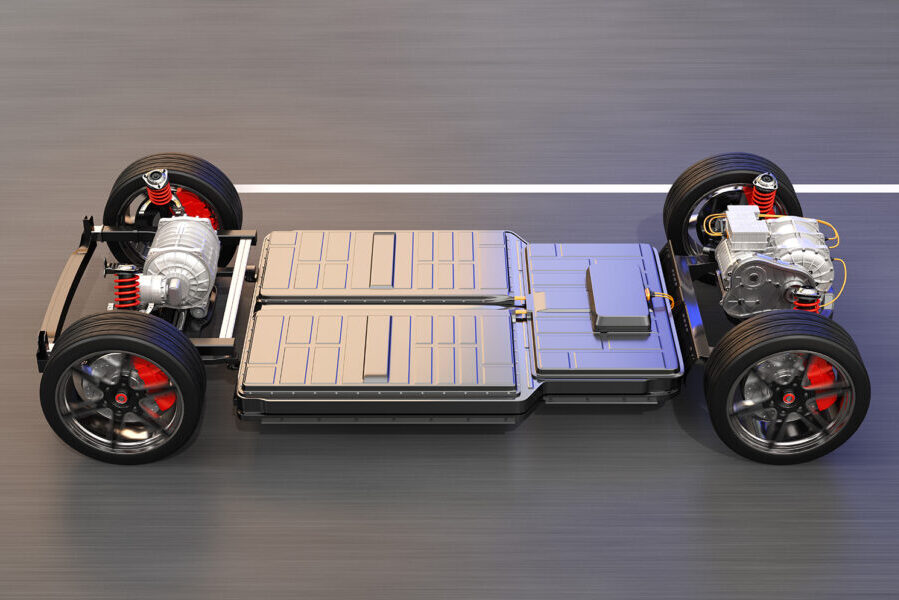

One of the fleet benefits of electric vehicles, beyond the environmental aspects, is that they have much simpler internal designs. The drivetrain typically has fewer than 20 moving parts, compared to the hundreds (or thousands) in an ICE. There’s no air intake, no engine block, no exhaust, no geared transmission.

However, this doesn’t mean that roadworthiness is any less essential or that fleets can relax their walk-round checks or proper maintenance. Here’s a few reasons why:

1. Major breakdown causes.

The most common causes of breakdown in the UK are defective tyres and a lack of fuel. Both of these are easily prevented by daily checks, regular

maintenance programmes, and a little planning. A driver who is checking tyre pressures, wheelnuts and tread depth daily doesn’t find their wheel making its own journey across the carriageway without them.

2. Details matter.

Even issues which do not seem to be critical or major repair jobs can have a profound impact on safety. A broken windscreen wiper may seem trivial – until it rains and the driver can no longer see the road. A broken indicator may seem minor – until another road user fails to be clairvoyant about your driver’s next manoeuvre and collides with them.

3. EV specific risks.

There are, of course, roadworthiness issues which apply specifically to EVs. Driver should know how to check the battery condition, cables and the charger connectors. Failure to do so could leave them stranded when they next try to charge up or, in a worst case scenario, undetected damage could cause a fire.

4. Safe loading.

Careful and safe loading is also a key issue for electric vehicles. Many car and van users keep everything they believe they may need in their vehicle. It should, of course, be properly stowed and safely secured. However, in an electric vehicle, where range is very sensitive to payload, carrying rarely used equipment makes little sense. Drivers should be encouraged to actively review loads, carry only what is necessary for that journey, and make sure all remaining gear is safely loaded and strapped.

5. Return on investment.

EVs cost about three times as much as an ICE equivalent. Although companies can recoup a return on their investment (typically over five to seven years), this

depends upon the vehicle staying in productive condition for that period. Encouraging careful husbandry of the vehicle is important to its longevity, its safety and its appearance, which can have an impact on your brand. Residual values may also depend on the condition of the vehicle at the end of its lease or first life.

6. Repair costs.

Although EVs have fewer moving parts, this does not mean that repair costs or inspections are cheaper. In fact, as workshops will need new bays, fittings and diagnostics, there is likely to be additional expense.

7. EV skills shortage.

According to the Institute of the Motor Industry only 6% of current motor mechanics are qualified to service EVs. The industry will require approximately 90,000 trained EV technicians by 2030 which will likely leave the industry with a 35,000 shortage. This means that having EVs off road due to damage or repair needs could involve significant expense, downtime and lost productivity.

8. Insurance costs.

Insurers are currently struggling to predict the cost of insuring EV fleets because they have a lack of historical data to indicate future repair costs. This makes it more important than ever for fleets to be able to demonstrate rigorous road risk management in order to keep premiums at affordable levels. Regardless of driveline, ensuring roadworthiness every day is essential.

You can learn more about daily walk round checks, regular vehicle inspection and maintenance schedules through our Van Driver Toolkit. These free resources offer excellent advice which often applies to other vehicle classes as well, and they can be used throughout your organisation.